- Comfort Service Programs

- Comfort Newsletter

- EMBA Up.Grade™ Program

- Installations

- Service Agreements

- Condition Testing

- OEM Spare Parts

- Upgrades and Rebuilds

- McKinley Upgrades

- Nano Block Upgrade

- Windows Computer Upgrade

- Refurbish Old or Used Equipment

EMBA COMFORT SERVICE PROGRAMS

The new powerful package that covers all your after-sales needs in one comfortable program. Make a selection in the EMBA Comfort toolbox, whether it is upgrading, service, parts or training, we have a tool for your machine and your crew. Increase your productivity and quality during the entire machine life cycle, with the tool that suits your need best.

Machine Technology. Now you can keep using your EMBA for many more years and still benefit from the latest technical developments. Don’t stand behind in inline technology or production data processing; up-date your EMBA now.

Machine Performance. Using the EMBA With the UP.GRADE™ program, you can increase your EMBA’s productivity as well and reduce set-up time and win over your competitors.

Product Quality. Your EMBA will be able to comply with the continuously increasing market requirements. Up-scale your print quality, folding accuracy and cut back your tolerances by using the available retrofits for your machine type

ORIGINAL PARTS

EMBA developed the machines and has therefore evaluated every single component in order to work in perfect harmony.

With EMBA Original Parts you know that every component is developed, tested and adapted exactly for your machine and model.

Make sure that your EMBA machine stays an EMBA.

- Full guarantee and quality

- Designed for best function and reliability

- One supplier for all your spare parts

EMBA PROFESSIONAL SERVICE

- Installation of new and pre-used machinery

- Technical support and guidance

- Trouble shooting via modem to your EMBA machine

- EMBA Condition Test

- EMBA Service Contract

EMBA ACADEMYTo enable you to optimize the performance of your EMBA and utilize the full benefits of the EMBA machine concept, EMBA proudly presents the EMBA Academy. Attending the EMBA Academy, your employees will improve their level of skills even further.

- First box saleable

- 1 to 2 minutes set-up

- Continuous increase of production output

The essential teamwork is also highlighted in order to create a comprehensive understanding for your entire staff involved in the process of making a box.

Join EMBA Comfort Newsletter

In order to ensure you will be updated with information regarding products and services from EMBA you are invited to join EMBA Comfort Newsletter.EMBA Comfort Newsletter will be sent via e-mail on a continuous basis direct to you with information that we believe will improve your productivity and quality. Whether it is about training or new innovations, it will always be something that might suit your specific need.

EMBA Comfort Newsletter

EMBA Performance Quality

Does your EMBA machine present the quality it used to? When was the last time your machine was serviced by a qualified EMBA Technician?

Perhaps you're aware of the issues, but don't know where to begin and want someone to come and smooth out the imperfections and leave you with a better tuned machine. Then take a look at our newest service:

The EMBA Comfort TuneUp

A Customized machine tuning with inspections tailored to

Your specific needs.Or is your machine in need of a more thorough check-up? Our well proven EMBA Condition Test with it's checklist will give you the answers to what's to be done in order to improve the entire machine's status.

EMBA Comfort TuneUp

The EMBA Comfort TuneUp is typically carried out over two days and will improve the performance of your EMBA machine right away.

There will be an inspection and investigation based on your description of issues.

The EMBA technician will run the machine at different speeds with all units activated to locate sources of error. Anything that might compromise the quality of your products.With every EMBA Comfort TuneUp you'll get:

- Inspection of Belts, Pulleys and Slotting Unit.

- Adjustment of the main Vacuum Belt and Tracking Device.

- Calibration of the machine.

Always with a focus on safety issues.At the end of the visit, a meeting will be held with operators and managers to go through the results and plan further improvements and recommendable upgrades.

EMBA Condition Test

Take the first steps towards improving the performance of Your EMBA

machine with our more extensive option.

Over a period of three days You will get a thorough check-up, following a list of more than 280 checkpoints, which will be verified by the EMBA technician, to identify necessary repairs, upgrades and settings.

You will then receive a summarized inspection protocol. Ready for discussions or further explanations. We want to ensure that you are fully aware of your machine's condition and its potential.

After the condition test you will receive a detailed report with;

- Prioritized actions, based on the test protocol.

- A list of recommended spare parts to improve your machine's condition.

- And last - but not least - the latest developed upgrades suitable for your needs.

Time is money!

If you like the sound of these previews, contact our Service department today at 440-360-7940 to get more information or a favorable quote on an EMBA Comfort TuneUp or an EMBA Condition Test. You will be on your way to getting your machine performance back on track in no time!

In order to ensure you will be updated with information regarding products and services from EMBA you are invited to join EMBA Comfort Newsletter.

Our Newsletter will be sent via e-mail on a continuous basis direct to you with information that we believe will improve your productivity and quality. Whether it's about training or new innovations, it will always be something that might suit your specific need.

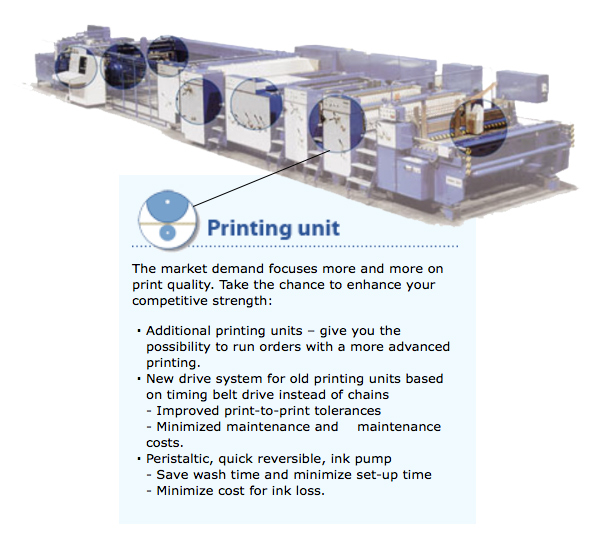

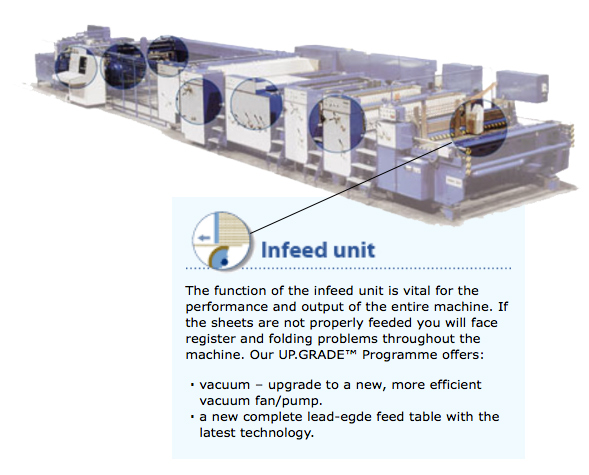

EMBA UP.GRADE™ Program

Machine Technology. Now you can keep using your EMBA for many more years and still benefit from the latest technical developments. Don’t stand behind in inline technology or production data processing – up-date your EMBA now.Machine Performance. Using the EMBA UP.GRADE™ program, you can increase your EMBA’s productivity as well and reduce set-up time and win over your competitors.

Product Quality. Your EMBA will be able to comply with the continuously increasing market requirements. Up-scale your print quality, folding accuracy and cut back your tolerances by using the available retrofits for your machine type.

Installations

EMBA will install new and used machines for you professionally, cost efficiently and on time. We will give you and your staff the technical guidance and support you need on a day-by-day basis.

Machine Installations:

Installing your new EMBA can be an insurmountable task. There is allot to consider and do from mechanical to electrical, vacuum systems and operator training. Fortunately we have extensive experience installing machinery. From the EMBA 140 to the 245 Ultima, and the McKinley machinery line too; we can handle all of them.

Your EMBA was built to exacting tolerances. Why shouldn’t the installation of such a precise machine be to the same exacting tolerances it was manufactured to? EMBA Machines require close installation tolerances not only for component alignment, but box quality as well.

Anyone can move and install a machine, but not everyone can install to EMBA tolerances.

Give us a call, we can help.

Service Agreements

Increase the productivity of your machines and improve the quality of your products by deciding for an EMBA Service Agreement. Continuous planned service visits by our experienced Service Technicians are the basis for a good performing and reliable machine. Regular repairs, adjustments and fine tuning as well as recommendations made by our technicians will not only increase performance and product quality, they will also significantly reduce maintenance costs and down times.

The EMBA Service Agreement consists of the following components:

- EMBA condition test

- Check up of the respective machine condition

- Recommendation for optimization of:

- Repair

- Maintenance

- Operation

- Recommended upgrades and spare parts

- Specification of activities for future visits

- Preferred EMBA spare parts supply

- Free utilization of our service-hotline

The EMBA Service Agreement is tailored to suit each customer, the number and length of the service interventions are based on the customer’s specific requirements.

General conditions:

The price includes all travel and accommodation expenses as well as allowance and hotel costs.

All specifications regarding the travel and working times applies to working days (Monday – Sunday), where applicable and to a daily working time between 07.00 and 18.00 h. Variations will be charged separately.

For safety reasons, 12 hours is the maximum number of hours EMBA technicians are allowed to work in any 24 hour period. technicians shall have a minimum of 10 consecutive hours away from the plant in any 24 hour period to ensure an ample rest period.

The customer keeps personnel available for assistance with operating, mechanical and electrical maintenance.

For best preparation of each service visit, the customer will inform EMBA Machinery Inc. before each visit about new defects and/ or issues with the machine.

Dates for the service visits are coordinated between the customer and EMBA Machinery Inc concerning the interests of the service team and the running of production. They are not subject to a fixed schedule.

Time schedule: Per agreement.

Condition Testing

Our Service Technicians are qualified to do the EMBA Condition Test, a special machine check program with a list of more than 280 checkpoints, developed to increase the quality of the products produced and avoid expensive unplanned production down time.

EMBA Condition Test

The way to avoid unplanned stops and maintain good quality and high production.

Before carrying out the condition test of your EMBA machine, we would like to supply You with information concerning a suitable timetable and what preparations you can make to obtain a positive result and to reduce the down-time of your machine to a minimum.

Preparations

- Clean the machine and the area around it.

- Check the spare parts stock for the machine.

- Make up a list of operation and maintenance problems, where every member of the machine personnel may express his opinion.

- Plan suitable orders so that a representative from EMBA can see the machine in normal operation at Your factory.

Condition test.

Part 1: Inspection of the machine in operation, inspection of the check points that should and can be carried out while running the machine ( 4-6 hours ).

Part 2: Production standstill, inspection of check points that can not be carried out while running the machine ( 10-12 hours )

Part 3: Summing up the results and suggestions for a program of possible measures ( 4-6 hours ).

More than 280 checkpointsSafety: Customer is requested to pay attention to the safety check in the end of this document and take actions to improve machine safety in case this is indicated. EMBA would also recommend that Your operation and maintenance personnel takes part in the whole inspection program. It provides a good information exchange and has a positive influence on the result of the test. Hours mentioned in the text are approximate and depend on the condition of the machine, equipment, customer's assistance etc.

Original (OEM) Spare Parts

EMBA Parts Manager |

McKinley Parts Manager |

|

Tracy Danesi Tel: 440-360-7940 Ext 212 Fax: 440-360-7934 After Hours: 440-360-7936 tracy.danesi@emba.com |

When EMBA develops a machine, every single component is evaluated for its integrated function in the whole. With EMBA Original Parts you know that every component is developed, tested and adapted exactly for your machine and model.

Only EMBA Original parts

- Come with full guarantee and original quality.

- Are designed for best function and reliability.

- Can be sourced through the same logistic chain as you EMBA machine.

- Will perfectly fit in the machine.

In the Spare Parts Centre in our Headquarters in Örebro, Sweden and in our Service Centres in Germany, Italy and the US we have a vast stock of parts readily available. That’s why we’re your reliable partner of choice for all your EMBA parts needs.

Make sure that your EMBA machine

stays an EMBA

Upgrades and Rebuilds

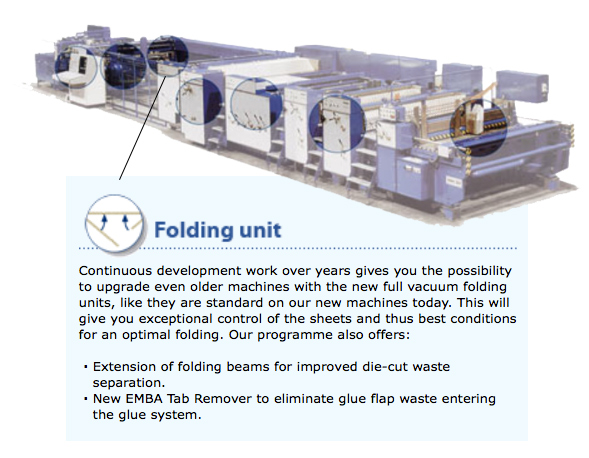

Years of development have resulted in a variety of upgrades for your EMBA machine. Through continuous improvements and technically innovative solutions on new machines you are able to benefit from the latest technology available for your EMBA. Meet the market demand of better print quality and smaller order sizes with your existing machine through the unique EMBA Upgrade Program.

Up-date, Up-grade, Up-scale…your machine technology.

Now you can keep using your mechanically reliable machines for many more years and still benefit from the latest technical developments. Don't stand behind in print technology or production data processing–up-date your equipment now.

Your machine performance. Using the upgrades the EMBA EASY.UP Programme offers, you can increase your machines production speed as well and cut back set-up time and win over your competitors.

Your product quality. Your machine will be able to make products you didn't dare to dream of. Up-scale your register accuracy, print quality and cut back your tolerances by using the available retrofits for your machine type. ...extend the lifetime of your EMBA.

McKinley Upgrades

SERVOFEED

Product quality starts right at the feeder. The accuracy of the feed table significantly influences all following process steps of your machine: print register, die cutting, slotting, scoring and fish tailing are determined here as well as production speed and downtimes.

The EMBA SERVOFEED is the synergy of the well-proven feed technique of the RS-Feeder and latest drive technology. It will process boards of all thicknesses and qualities – even if they're not quite as flat as they're supposed to be…

A strong vacuum gives focused and flexible support to the feeding process: It can be adjusted in both, power as well as distribution to perfectly match the individual requirements of each job on your machine.

The EMBA SERVOFEED is designed to be fully modular and can be easily adjusted to match working width and room requirements of machines of all types and makes. The integration into the machine is simple: Since the electronic integration requires no mechanical link to the machine's main drive the EMBA S ERVOFEED can be installed in record time.

Using the computer control with comfortable graphic displays, all parameters can be easily entered in the operator's menu and centrally controlled: register position, motorised table movements, front gates and vacuum settings.

FLEXO PRINT SECTION

By installing additional print sections into your line you will:

- increase the usage of existing machines

- integrate the latest print technology

- improve printing quality and register accuracy

Chose from the following options:

- Manual or motorized axial adjustment

- Manual or motorized nip control

- Anilox roll chrome plated steel or laser engraved ceramic

- Free specification of sterreo thickness, mounting system, etc.

VACUUM TRANSPORT

The most precise way to transport any size of sheet through all sections of the line is to use our vacuum transport system which offers:

- Highly accurate board transfer for high quality printing

- No contact to print side

- Better and faster drying of the ink through a constant air circulation

- Easy access to print cylinder for mounting and cleaning of stereos

Features include:

- Transport shafts designed for zero slipping

- Maintenance free roller bearings

- Split frames for vibration-free operation

HARMONIC DRIVE REGISTER

In order to increase register accuracy, retrofit your machine with register control from Harmonic Drive® Technologies and benefit from these advantages:

- Excellent positioning accuracy and repeatability

- High torque capacity

- Zero back-lash

- High single-stage reduction ratio

- High efficiency

- Minimal wear, long life

- High torsional stiffness

- 0,1 mm accuracy

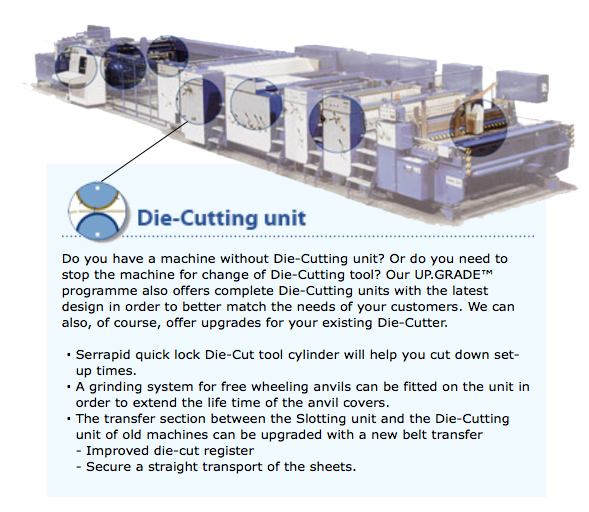

TRANSFER SECTION

The Transfer Section is installed between the last print unit and the rotary die cutter. The increased distance between printing and cutting offers:

- Better print quality on larger sheets

- Improved drying of ink

- Higher production speed

- Less dust contamination and related maintenance

- Reduced back-lash impact on print quality

- Motorized nip control adjustment

- Room for additional drying unit

- No need for set-up with format change

COMPUTER CONTROL SYSTEM

Just because your machine is a few years old doesn’t mean that it needs to stand behind in control technology. We can offer a variety of solutions to control and even store the settings of the motorized axes. Using the latest machine control systems, bus-technology, common interfaces and customized solutions for your production data processing, some possible functions are:

- Register setting

- Nip control

- Lateral print cylinder adjustment

- Vacuum settings

- Side pushers etc.

MAGELIS TOUCH SCREEN upgrades are now available for your McKinley machines

Available for:

- Feed Units

- Print Units

- Slotting / Diecut Units

- Flexo-Folder Gluers and

- All McKinley Stacker Units

Upgrade your screens for:

- Faster access to menu options.

- Operator friendly design and navigation.

- Direct mount and replacement for obsolete screens.

- Optional inch/metric selection.

Applicable to McKinley Machine Serial Numbers 25099 thru 33404 Please contact us for details.For additional details and machine applications, please contact:

Tracy Danesi

Tel: 440-360-7940 Ext 212

Fax: 440-360-7934

After Hours: 440-360-7936

tracy.danesi@emba.com

TSX Nano Block Upgrade

WARNING! Major Downtime Ahead. Unfortunately obsolescence of electronic components is nowadays a stark reality. If your McKinley is equipped with the Modicon Nano block remote I/O system (shown below), then these components are no longer available from the manufacturer. Spare part replacements are virtually non-existant.

![]()

Take control of your controls with a new Modicon TSX Micro PLC. Upgrade your Modicon Nano Block system with the Modicon Micro system from EMBA- McKinley and you will overcome the problem of unobtainable spare parts for the old Nano system.

After upgrading you will have access to both spare parts and professional support for secured future functionality.

To avoid the inevitable downtime contact:

McKinley Parts Manager Tracy Danesi

Tel: 440-360-7940 Ext 212

Fax: 440-360-7934

After Hours: 440-360-7936

tracy.danesi@emba.com

Windows 3.11 computer - Update

Windows 3.11 computers are now OBSOLETE and no longer available. This means that you should give serious consideration to replacing your existing Windows 3.11 computers with a more modern version. We can offer an updated Windows version depending on your machine configuration. We strongly recommend making a planned replacement of the computer system, since a computer crash on your Windows 3.11 will increase the risk of significant production downtime.

Contact EMBA customer support today for an upgrade quotation.

EMBA Parts Manager Dan Velickovic

Tel: 440-360-7940 Ext 210

Fax: 440-360-7934

After Hours: 440-360-7936

dan.velickovic@emba.com

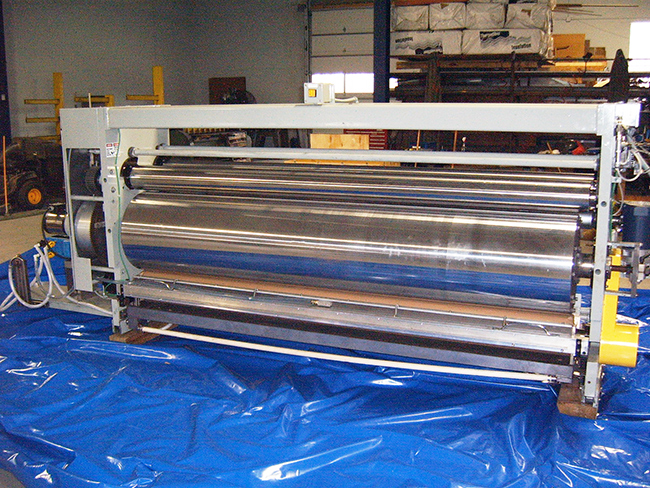

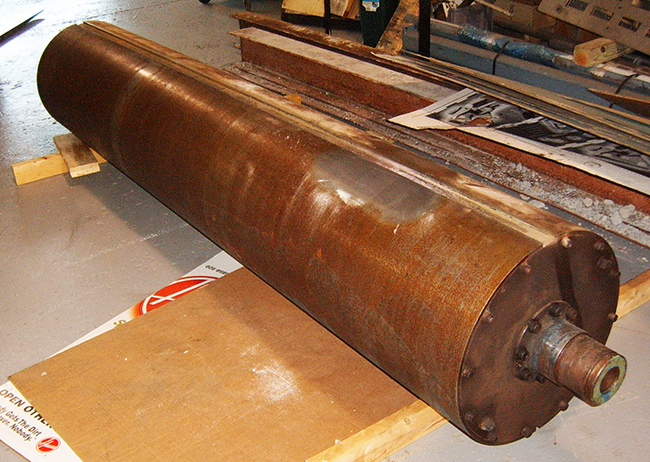

Refurbish Old or Used Equipment

EMBA can refurbish used or old equipment, restoring sections to their original specifications and/or upgrading them to current standards at a fraction of the cost of new equipment.

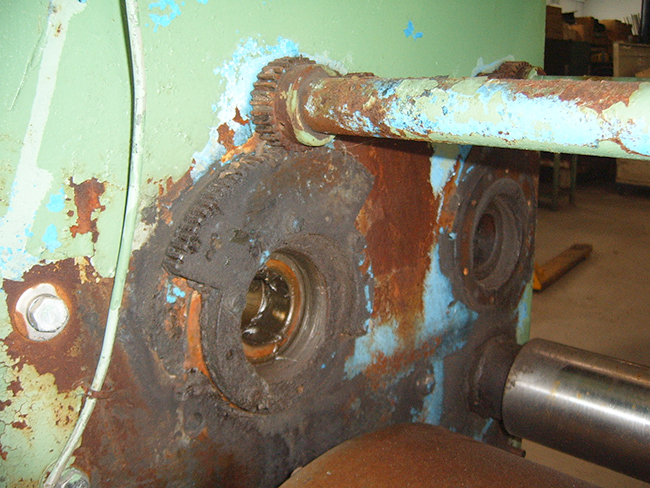

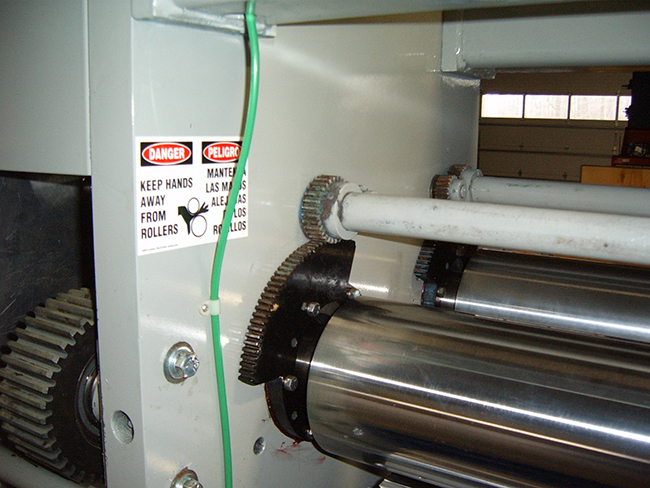

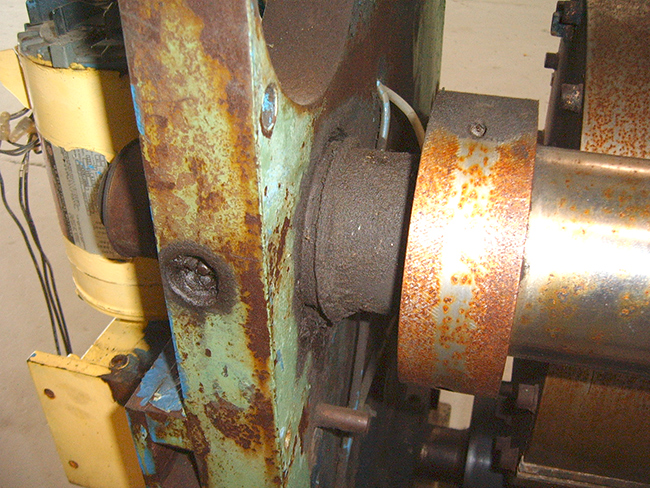

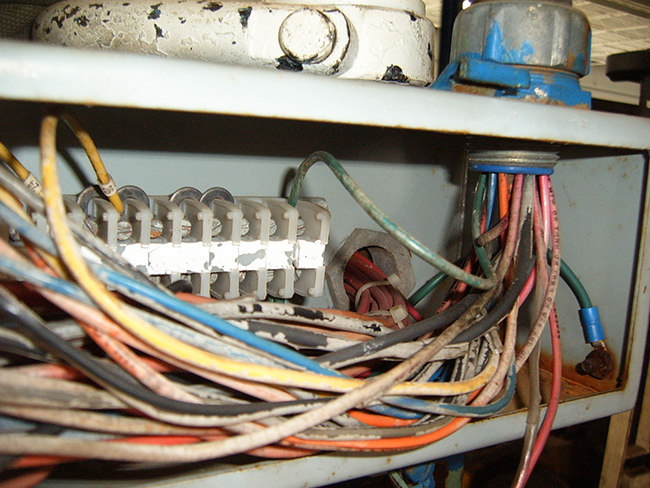

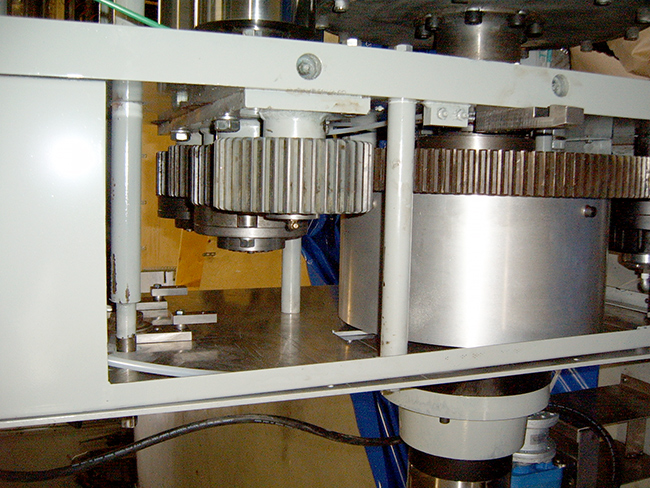

Below are some AFTER and BEFORE pictures of a McKinley Machine, 66" x 110" print station from a 1987 Rotary die cutter. The refurbished print station is a good economical alternative compared to a new section.

Give us a call today and let's discuss ways that we can save you money while providing the quality, reliability and longevity you have come to expect from EMBA and McKinley equipment.