-

McKinley

- Rotary Die Cutters

- Flexo Folder Gluers

- Jumbo Machines

- Nano Block Upgrade

- McKinley Upgrades

- Drop-in Replacements

McKinley Machinery

History

EMBA Machinery Inc, part of the Stockholm, Sweden based Berg Group, relocated its North American headquarters from Atlanta, Georgia to the Cleveland, Ohio area, on January 12, 2006.

Based at the McKinley Machinery, Inc. facilities in Avon, Ohio, acquired by Berg Group in 2005, the move consolidated new machinery sales, parts, service, and technical support operations for both the EMBA and the McKinley lines of corrugated board converting equipment. In addition, EMBA resumed the production of the McKinley line of Rotary Die Cutters, Flexo Folder Gluers, Jumbo Inline Machines, and High Board Line architecture machines.

The move allowed for better use of McKinley’s established local resources for manufacturing, and created a more streamlined and effective organization in support of the existing EMBA and McKinley customer base.

Today

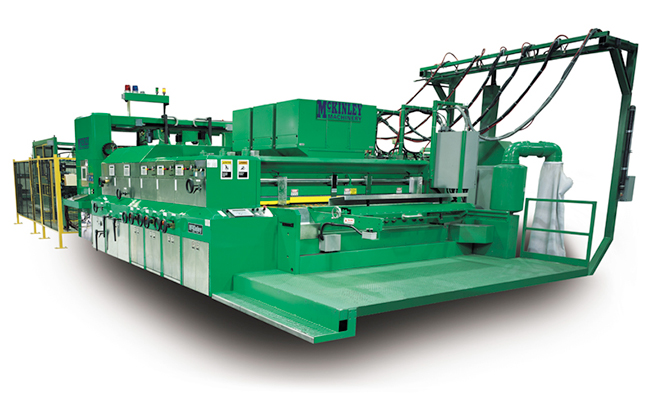

EMBA, now located in Westlake, Ohio (USA) is a leading manufacturer of state of the art rotary diecutters, flexo folder gluers, high graphics printers, and jumbo printer slotters for the corrugated industry. The McKinley Premier Rotary Diecutters feature Sun lead edge feeders, vacuum transfer, reverse angle or chamber doctor blade ink metering, independent servo drives of all units, anvil grinding, quick lock die mounting, touch screen operator control systems and much more.

The McKinley Flexo Folder Gluers feature motorized dual slotting shafts, optional precreaser, extended vacuum folding section, positive gap control, top loading counter ejector and much more. The McKinley High Graphics Printers are high board line quick set up machines with independent drives, vacuum transfer, advanced ink metering and exceptional register control for super high quality printing on corrugated board.

EMBA 66" x 190" Jumbo Flexo Folder Gluer.

Rotary Die Cutters

Premier™ Rotary Die Cutters Closed-Coupled Units

- 66" x 80" (1676 x 2000 mm)

- 66" x 110 " (1676 x 2800 mm)

- 66" x 130" (1676 x 3300 mm)

Flexo Folder Gluers

Premier™ Flexo Folder Gluers Closed-Coupled Units

- 50" x 110" (1250 x 2800 mm)

- 50" x 130" (1250 x 3300 mm)

- 66" x 130 " (1676 x 3300 mm)

Jumbo Machines

Premier™ Jumbo Rotary Die Cutter

- 66" x 150" (1676 x 3810 mm)

- 66" x 170" (1676 x 4318 mm)

- 66" x 190" (1676 x 4826 mm)

- 88" x 210" (2235 x 5486 mm)

Premier™ Flexo Folder Gluer

- 66" x 150" (1676 x 3810 mm)

- 66" x 170" (1676 x 4318 mm)

- 66" x 190" (1676 x 4826 mm)

- 88" x 210" (2235 x 5486 mm)

TSX Nano Block Upgrade

WARNING! Major Downtime Ahead. Unfortunately obsolesence of electronic components is nowadays a stark reality. If your McKinley is equipped with the Modicon Nano block remote I/O system (shown below), then these components are no longer available from the manufacturer. Spare part replacements are virtually non-existant.

![]()

Take control of your controls with a new Modicon TSX Micro PLC. Upgrade your Modicon Nano Block system with the Modicon Micro system from EMBA- McKinley and you will overcome the problem of unobtainable spare parts for the old Nano system.

After upgrading you will have access to both spare parts and professional support for secured future functionality.

To avoid the inevitable downtime contact:

McKinley Parts Manager Tracy Danesi

Tel: 440-360-7940 Ext212

Fax: 440-360-7934

After Hours: 440-360-7936

tracy.danesi@emba.com

McKinley Upgrades

SERVOFEED

Product quality starts right at the feeder. The accuracy of the feed table significantly influences all following process steps of your machine: print register, die cutting, slotting, scoring and fish tailing are determined here as well as production speed and downtimes.

The EMBA SERVOFEED is the synergy of the well-proven feed technique of the RS-Feeder and latest drive technology. It will process boards of all thicknesses and qualities – even if they're not quite as flat as they're supposed to be…

A strong vacuum gives focused and flexible support to the feeding process: It can be adjusted in both, power as well as distribution to perfectly match the individual requirements of each job on your machine.

The EMBA SERVOFEED is designed to be fully modular and can be easily adjusted to match working width and room requirements of machines of all types and makes. The integration into the machine is simple: Since the electronic integration requires no mechanical link to the machine's main drive the EMBA S ERVOFEED can be installed in record time.

Using the computer control with comfortable graphic displays, all parameters can be easily entered in the operator's menu and centrally controlled: register position, motorised table movements, front gates and vacuum settings.

FLEXO PRINT SECTION

By installing additional print sections into your line you will:

- increase the usage of existing machines

- integrate the latest print technology

- improve printing quality and register accuracy

Chose from the following options:

- Manual or motorized axial adjustment

- Manual or motorized nip control

- Anilox roll chrome plated steel or laser engraved ceramic

- Free specification of sterreo thickness, mounting system, etc.

VACUUM TRANSPORT

The most precise way to transport any size of sheet through all sections of the line is to use our vacuum transport system which offers:

Highly accurate board transfer for high quality printing

- No contact to print side

- Better and faster drying of the ink through a constant air circulation

- Easy access to print cylinder for mounting and cleaning of stereos

Features include:

- Transport shafts designed for zero slipping

- Maintenance free roller bearings

- Split frames for vibration-free operation

HARMONIC DRIVE REGISTER

In order to increase register accuracy, retrofit your machine with register control from Harmonic Drive® Technologies and benefit from these advantages:

Excellent positioning accuracy and repeatability

- High torque capacity

- Zero back-lash

- High single-stage reduction ratio

- High efficiency

- Minimal wear, long life

- High torsional stiffness

- 0,1 mm accuracy

TRANSFER SECTION

The Transfer Section is installed between the last print unit and the rotary die cutter. The increased distance between printing and cutting offers:

- Better print quality on larger sheets

- Improved drying of ink

- Higher production speed

- Less dust contamination and related maintainance

- Reduced back-lash impact on print quality

- Motorized nip control adjustment

- Room for additional drying unit

- No need for set-up with format change

COMPUTER CONTROL SYSTEM

Just because your machine is a few years old doesn’t mean that it needs to stand behind in control technology. We can offer a variety of solutions to control and even store the settings of the motorized axes. Using the latest machine control systems, bus-technology, common interfaces and customized solutions for your production data processing, some possible functions are:

- Register setting

- Nip control

- Lateral print cylinder adjustment

- Vacuum settings

- Side pushers etc.

EMBA UPGRADE PROGRAM: FOR EMBA INLINER

We offer a large range of upgrades for your EMBA FFG. Please contact sales for detailed information.

Magelis touch screen upgrades are now available for your McKinley machines

Available for:

- Feed Units

- Print Units

- Slotting / Diecut Units

- Flexo-Folder Gluers and

- All McKinley Stacker Units

Upgrade your screens for:

- Faster access to menu options.

- Operator friendly design and navigation.

- Direct mount and replacement for obsolete screens.

- Optional inch/metric selection.

Applicable to McKinley Machine Serial Numbers 25099 thru 33404 Please contact us for details.For additional details and machine applications, please contact:

Tracy Danesi

Tel: 440-360-7940 Ext 212

Fax: 440-360-7934

After Hours: 440-360-7936

tracy.danesi@emba.com

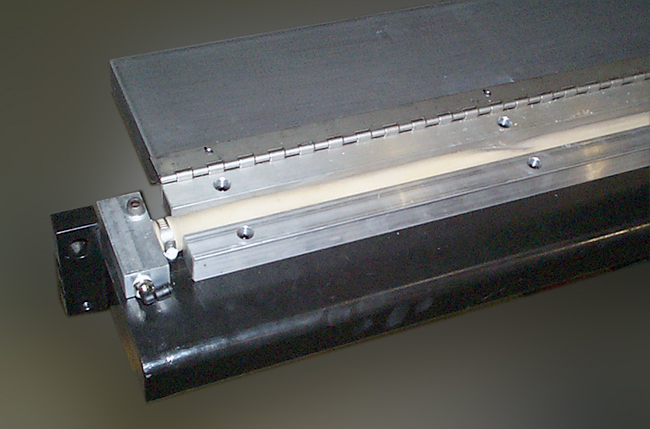

McKinley Drop-in Replacements

EMBA supplies the complete McKinley Machinery line of OEM drop in replacement blade units. Other options include replacement of wear parts for the blade units such as (blade holder, clamp, hinges, bladder blocks etc.) allowing you to rebuild them yourself. Our blade holders and clamps are precision machined aluminum and hard coated for durability. We also fabricate blade holders and clamps out of stainless steel providing a much longer life span.

Drop-in replacement blade unit

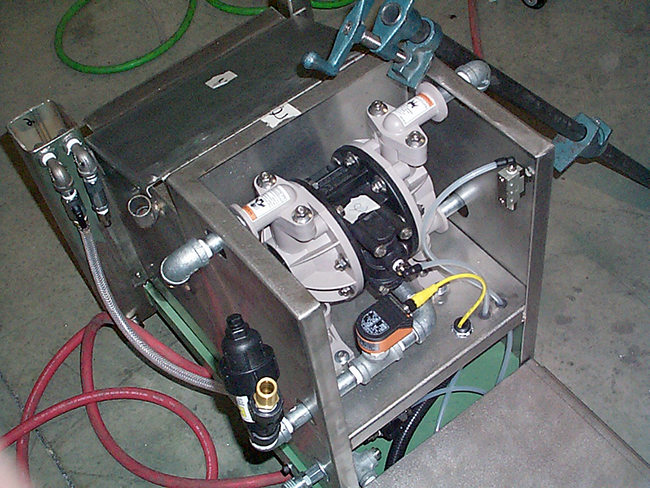

We supply replacement ARO pumps converted and ready to install, ink flow sensors, slid out ink pan to replace bolt in factory ink pans and we stock all OEM replacement anilox lift cylinders.

We stock all the replacement ink pumps, filters and ink flow censors for the McKinley line.

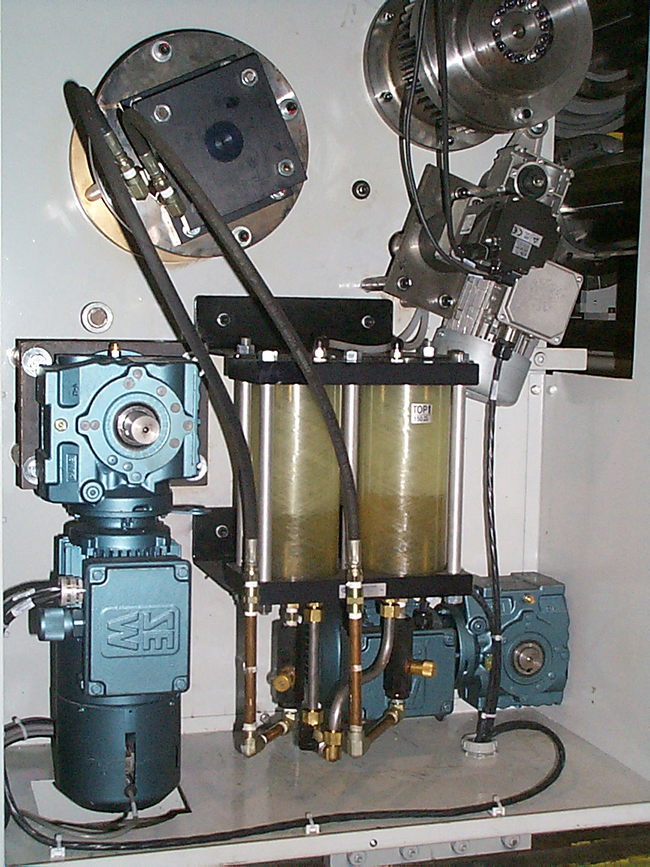

Tired of replacing the original leaky hydraulic units and cylinders? Take a look at EMBA’s Air over Oil upgrade to completely eliminate the old hydraulic tanks for the McKinley line, resulting in more affordable replacement parts.

Air Over Oil McKinley Upgrades

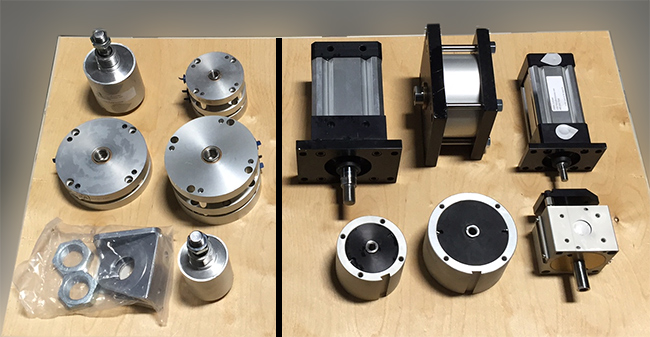

We stock anilox lift cylinders and hydraulic oscillation cylinders for all the McKinley Machines.

Anilox Lift & Hydraulic Oscillation Cylinders

For additional details and machine applications, please contact:

Tracy Danesi

Tel: 440-360-7940 Ext 212

Fax: 440-360-7934

After Hours: 440-360-7936

tracy.danesi@emba.com